轻钢龙骨用多大电统焊

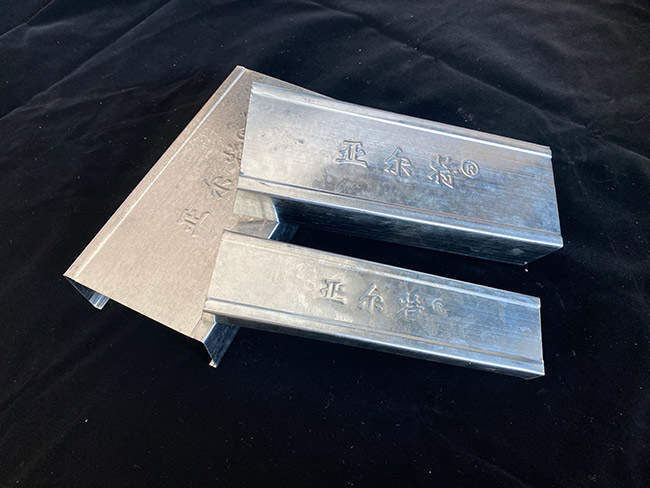

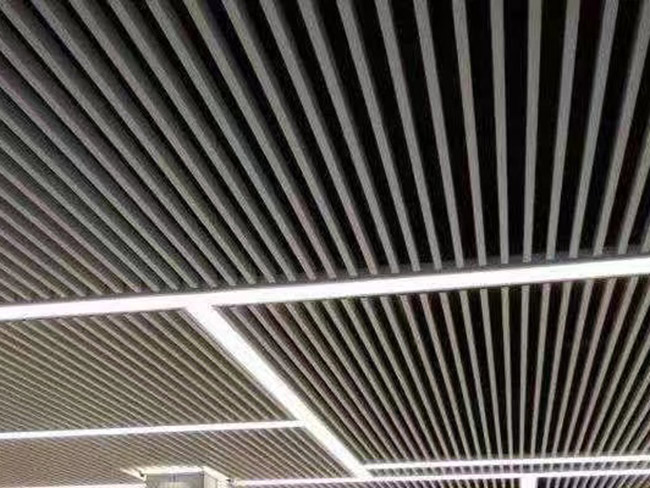

Light steel keel is a kind of building material which is widely used in the construction industry. It is made of thin steel strips and has a high strength and good stability. In order to ensure the quality of the light steel keel, it is necessary to use electric resistance welding (ERW) to weld the steel strips together.

ERW welding is a welding process that uses electrical current to heat and melt the edges of two pieces of metal, and then press them together to form a strong bond. The welding process is fast and efficient, and the welded joint is strong and reliable.

When welding light steel keel, the welding current should be selected according to the thickness of the steel strip. Generally, the welding current should be between 80 and 120A. The welding speed should be adjusted according to the welding current. The welding speed should be slow when the welding current is low, and the welding speed should be fast when the welding current is high.

In addition, the welding time should be controlled. The welding time should not be too long, otherwise the welded joint will be too brittle and easy to break. The welding time should be controlled within 0.5-1.5 seconds.

In conclusion, electric resistance welding is an important process for welding light steel keel. The welding current, welding speed and welding time should be properly adjusted according to the thickness of the steel strip to ensure the quality of the welded joint.

冀公网安备 13102602000572号

冀公网安备 13102602000572号